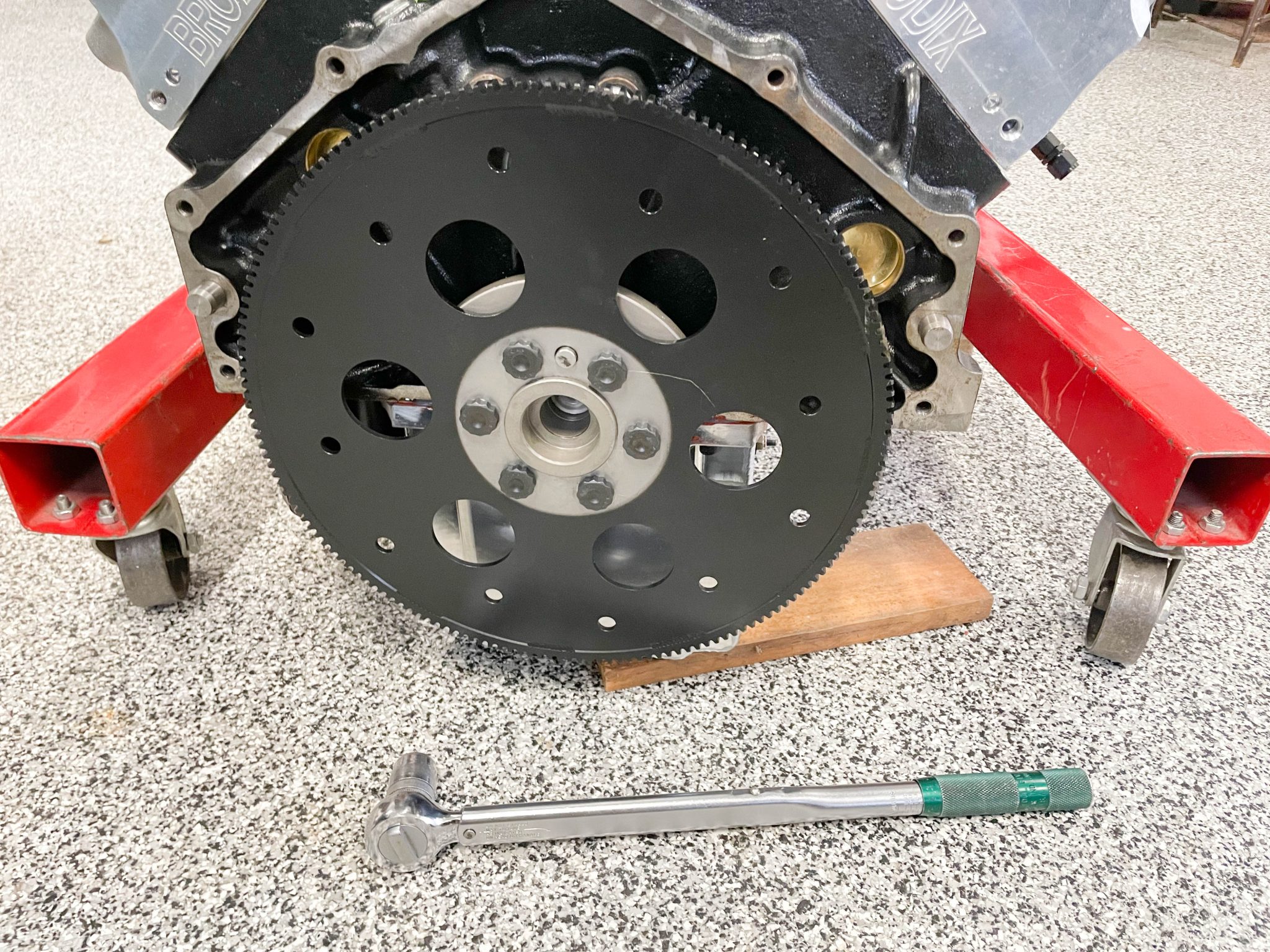

Flexplate To Crankshaft Bolt Torque . I have some nice new grad. Then you can find the correct flex plate, either in a stock application or a swap application fitment. my question is in regard to the torque specs for the ten (10) bolts which hold the flex plate to the crankshaft. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). 1) torque all bolts to 30nm in a star pattern. Bolts are single use, so make sure you use new. the more important questions will be type of block/crank, what transmission/torque converter you’re bolting up to said block, and more. 2) turn all bolts an extra 90°, again in a star pattern.

from www.onallcylinders.com

the more important questions will be type of block/crank, what transmission/torque converter you’re bolting up to said block, and more. my question is in regard to the torque specs for the ten (10) bolts which hold the flex plate to the crankshaft. Then you can find the correct flex plate, either in a stock application or a swap application fitment. 1) torque all bolts to 30nm in a star pattern. Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). I have some nice new grad. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. Bolts are single use, so make sure you use new. 2) turn all bolts an extra 90°, again in a star pattern.

The Malleable Connection Flexplates & Flexplate Installation Tips

Flexplate To Crankshaft Bolt Torque I have some nice new grad. 2) turn all bolts an extra 90°, again in a star pattern. Bolts are single use, so make sure you use new. I have some nice new grad. 1) torque all bolts to 30nm in a star pattern. Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. Then you can find the correct flex plate, either in a stock application or a swap application fitment. my question is in regard to the torque specs for the ten (10) bolts which hold the flex plate to the crankshaft. the more important questions will be type of block/crank, what transmission/torque converter you’re bolting up to said block, and more.

From repairfixamosarftl.z19.web.core.windows.net

What Is Flexplate Flexplate To Crankshaft Bolt Torque Bolts are single use, so make sure you use new. Then you can find the correct flex plate, either in a stock application or a swap application fitment. my question is in regard to the torque specs for the ten (10) bolts which hold the flex plate to the crankshaft. the more important questions will be type of. Flexplate To Crankshaft Bolt Torque.

From dxoaiisdq.blob.core.windows.net

Torque Converter Flexplate Specs at Latoya Stewart blog Flexplate To Crankshaft Bolt Torque Bolts are single use, so make sure you use new. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. 1) torque all bolts to 30nm in a star pattern. the more important questions will be type of block/crank, what transmission/torque converter you’re bolting up to said. Flexplate To Crankshaft Bolt Torque.

From www.youtube.com

Torque Converter to Flexplate Bolts Starter Install vid 8 GM Chevy Tahoe Vortec LS Engine Flexplate To Crankshaft Bolt Torque Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). Then you can find the correct flex plate, either in a stock application or a swap application fitment. I have some nice new grad. Bolts are single use, so make sure you use new. 2) turn all. Flexplate To Crankshaft Bolt Torque.

From www.speedspares.net

Flexplate To Crank Bolts XA XB XC XD XE Cleveland V8 & 6 Cylinder Rare Spares Flexplate To Crankshaft Bolt Torque 2) turn all bolts an extra 90°, again in a star pattern. Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). Bolts are single use, so make sure you use new. my question is in regard to the torque specs for the ten (10) bolts. Flexplate To Crankshaft Bolt Torque.

From einvoice.fpt.com.vn

LS Engine Flexplate Fitment Guide, 45 OFF Flexplate To Crankshaft Bolt Torque Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). the more important questions will be type of block/crank, what transmission/torque converter you’re bolting up to said block, and more. 2) turn all bolts an extra 90°, again in a star pattern. my question is. Flexplate To Crankshaft Bolt Torque.

From www.justanswer.com

Could You Help me, I need torque specs for flexplate internal and external. I speak a little Flexplate To Crankshaft Bolt Torque I have some nice new grad. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. 2) turn all bolts an extra 90°, again in a star pattern. Then you can find the correct flex plate, either in a stock application or a swap application fitment. 1) torque. Flexplate To Crankshaft Bolt Torque.

From www.speedspares.net

FK1038 FLEXPLATE TO CRANK BOLT SET EHVK LCUC Flexplate To Crankshaft Bolt Torque Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). 2) turn all bolts an extra 90°, again in a star pattern. my question is in regard to the torque specs for the ten (10) bolts which hold the flex plate to the crankshaft. the. Flexplate To Crankshaft Bolt Torque.

From www.twistedtorqueracing.com

LS 6Bolt Crankshaft to 4L60/4L70 Flexplate Kit Twisted Torque Inc. Flexplate To Crankshaft Bolt Torque 2) turn all bolts an extra 90°, again in a star pattern. I have some nice new grad. 1) torque all bolts to 30nm in a star pattern. Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). i am wondering if there is a. Flexplate To Crankshaft Bolt Torque.

From board.moparts.org

440 flexplate bolt torque? Moparts Forums Flexplate To Crankshaft Bolt Torque Then you can find the correct flex plate, either in a stock application or a swap application fitment. I have some nice new grad. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. 1) torque all bolts to 30nm in a star pattern. Install 2 new bolts. Flexplate To Crankshaft Bolt Torque.

From www.ebay.com.au

Holden Flex Plate To Crankshaft Bolt For 253 308 Engine Auto Crank 4.2L 5.0L eBay Flexplate To Crankshaft Bolt Torque 1) torque all bolts to 30nm in a star pattern. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. 2) turn all bolts an extra 90°, again in a star pattern. Then you can find the correct flex plate, either in a stock application or a swap. Flexplate To Crankshaft Bolt Torque.

From 209yota1.com

Flex Plate Bolt To Torque Converter Genuine 19872004 Yota1 Performance, Inc. Flexplate To Crankshaft Bolt Torque Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. Then you can find the correct flex plate, either in a stock application or a swap. Flexplate To Crankshaft Bolt Torque.

From ceqjqgnt.blob.core.windows.net

Ls Arp Flexplate Bolt Torque at Donna Hoffmann blog Flexplate To Crankshaft Bolt Torque Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). the more important questions will be type of block/crank, what transmission/torque converter you’re bolting up to said block, and more. 1) torque all bolts to 30nm in a star pattern. i am wondering if. Flexplate To Crankshaft Bolt Torque.

From www.dieselplace.com

Question Torque converter to flexplate bolt torque spec Diesel Place Flexplate To Crankshaft Bolt Torque 1) torque all bolts to 30nm in a star pattern. I have some nice new grad. Then you can find the correct flex plate, either in a stock application or a swap application fitment. Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). 2) turn. Flexplate To Crankshaft Bolt Torque.

From www.rarespares.net.au

Holden Flexplate to Crank Bolt Kit 253/308 HQ HJ HX HZ WB VB VC VH VK VL Commodore BS1030 Flexplate To Crankshaft Bolt Torque I have some nice new grad. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. my question is in regard to the torque specs for the ten (10) bolts which hold the flex plate to the crankshaft. Then you can find the correct flex plate, either in. Flexplate To Crankshaft Bolt Torque.

From www.moparpartsgiant.com

52118473 Genuine Mopar FLEXPLATETORQUE CONVERTER DRIVE Flexplate To Crankshaft Bolt Torque Bolts are single use, so make sure you use new. I have some nice new grad. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. the more important questions will be type of block/crank, what transmission/torque converter you’re bolting up to said block, and more. 1). Flexplate To Crankshaft Bolt Torque.

From www.atesteo.com

Flexplate for new standard in measuring torque ATESTEO Flexplate To Crankshaft Bolt Torque 2) turn all bolts an extra 90°, again in a star pattern. Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). my question is in regard to the torque specs for the ten (10) bolts which hold the flex plate to the crankshaft. the. Flexplate To Crankshaft Bolt Torque.

From www.dragzine.com

Flexplate Technology And Choosing The Flexplate For You Flexplate To Crankshaft Bolt Torque Bolts are single use, so make sure you use new. 2) turn all bolts an extra 90°, again in a star pattern. I have some nice new grad. i am wondering if there is a torque spec for attaching the flex plate to the end of the crank. my question is in regard to the torque specs for. Flexplate To Crankshaft Bolt Torque.

From www.powerstroke.org

E4OD Flexplate to crank bolt size and length Ford Powerstroke Diesel Forum Flexplate To Crankshaft Bolt Torque 1) torque all bolts to 30nm in a star pattern. I have some nice new grad. Install 2 new bolts (2) in location at the top and bottom of the flex plate bolt pattern allowing the flex plate (2). my question is in regard to the torque specs for the ten (10) bolts which hold the flex plate. Flexplate To Crankshaft Bolt Torque.